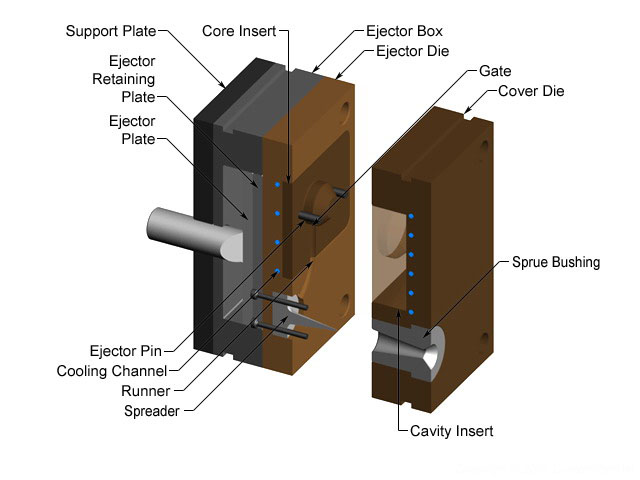

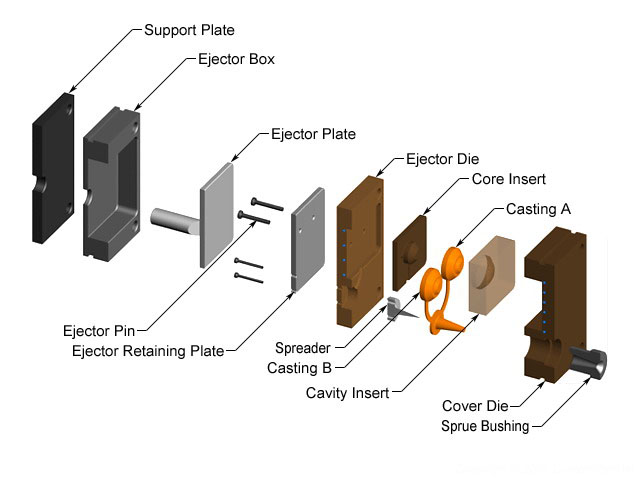

The dies into which the molten metal is injected are the custom

tooling used in this process. The dies are typically composed of

two halves - the cover die, which is mounted onto a stationary

platen, and the ejector die, which is mounted onto a movable

platen. This design allows the die to open and close along its

parting line. Once closed, the two die halves form an internal

part cavity which is filled with the molten metal to form the

casting. This cavity is formed by two inserts, the cavity insert

and the core insert, which are inserted into the cover die and

ejector die, respectively. The cover die allows the molten metal

to flow from the injection system, through an opening, and into

the part cavity. The ejector die includes a support plate and

the ejector box, which is mounted onto the platen and inside

contains the ejection system. When the clamping unit separates

the die halves, the clamping bar pushes the ejector plate

forward inside the ejector box which pushes the ejector pins

into the molded part, ejecting it from the core insert.

Multiple-cavity dies are sometimes used, in which the two die

halves form several identical part cavities.

Die channels

The flow of molten metal into the part cavity requires several

channels that are integrated into the die and differs slightly

for a hot chamber machine and a cold chamber machine. In a hot

chamber machine, the molten metal enters the die through a piece

called a sprue bushing (in the cover die) and flows around the

sprue spreader (in the ejector die). The sprue refers to this

primary channel of molten metal entering the die. In a cold

chamber machine, the molten metal enters through an injection

sleeve. After entering the die, in either type of machine, the

molten metal flows through a series of runners and enters the

part cavities through gates, which direct the flow. Often, the

cavities will contain extra space called overflow wells, which

provide an additional source of molten metal during

solidification. When the casting cools, the molten metal will

shrink and additional material is needed. Lastly, small channels

are included that run from the cavity to the exterior of the

die. These channels act as venting holes to allow air to escape

the die cavity. The molten metal that flows through all of these

channels will solidify attached to the casting and must be

separated from the part after it is ejected. One type of channel

that does not fill with material is a cooling channel. These

channels allow water or oil to flow through the die, adjacent to

the cavity, and remove heat from the die.

Die

assembly – Open (Hot chamber) Die assembly – Opened (Cold chamber)

Die assembly - Closed (Hot chamber) Die assembly - Closed (Cold chamber)

Die

assembly - Exploded view (Hot chamber) Die assembly - Exploded view (Cold chamber)

Die Design

In addition to these many types of channels, there are other

design issues that must be considered in the design of the dies.

Firstly, the die must allow the molten metal to flow easily into

all of the cavities. Equally important is the removal of the

solidified casting from the die, so a draft angle must be

applied to the walls of the part cavity. The design of the die

must also accommodate any complex features on the part, such as

undercuts, which will require additional die pieces. Most of

these devices slide into the part cavity through the side of the

die, and are therefore known as slides, or side-actions. The

most common type of side-action is a side-core which enables an

external undercut to be molded. Another important aspect of

designing the dies is selecting the material. Dies can be

fabricated out of many different types of metals. High grade

tool steel is the most common and is typically used for

100-150,000 cycles. However, steels with low carbon content are

more resistant to cracking and can be used for 1,000,000 cycles.

Other common materials for dies include chromium, molybdenum,

nickel alloys, tungsten, and vanadium. Any side-cores that are

used in the dies can also be made out of these materials.

HOME PAGE | CASTING BLOG | CONTACT US |